WTF-J’s exhaust system gives proof to the notion that the downside to stuffing a V8 into a Jeep that was originally designed using an in-line 4-cyl and later upgrades to an in-line 6-cyl is that you eventually run out of room. Real estate under the WTF-J’s hood is getting to be more precious than the Ginza in Tokyo. The challenge in this chapter is the task of merging the output from the two exhaust headers into a single exhaust and route it to the back.

The master fabricator in me said; "let’s build a crossover pipe." Sounded like a good plan, since OTC crossovers are very expensive and custom crossovers are almost a religious experience (i.e. OMFG) in terms of pricing. I watched enough Monster Garage and American Chopper episodes to convince myself that fabricating an exhaust was e-a-s-y. I ordered some U-Bends, a 2.5" header connector kit, an O2 bung, and a 2.5"-3" transition pipe from Speedway Motors and we were off to the races. (Speedway is a great place for good prices on racing parts.)

The exhaust would also provide an opportunity to learn a new welding process with Silicon Bronze filler. Sili-Bronze has a much lower melting point and in the TIG process is more like brazing. The advantage is that with less heat, there is a significantly lower likelihood of warping and burn through. The golden color of the weldment is also pretty neat.

Fast forward about four days of trial and error fabrication and voila!

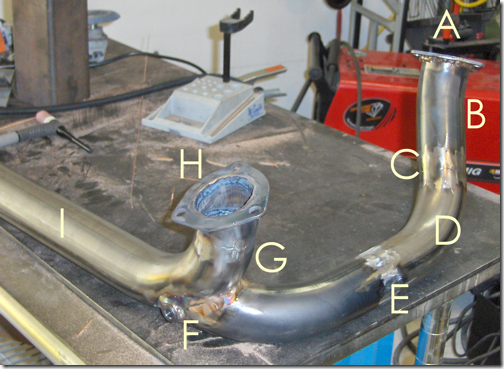

I added the reference points to explain what I learned in the fabrication process.

"A" & "H" are fixed points on the engine and by fixed, even the orientation of the three holes on the flanges are "non negotiable." Pipe "B" was the first piece. It has a subtle bend that is needed to clear the bottom of the engine on the driver’s side. Once that orientation is established, I could tack weld it to flange "A" The next step was to cut the radius "D" and then use "B" to establish the depth of the crossover. It’s a bit of a three-dimensional puzzle, as "D" needs to be properly oriented front-to-back, up-down, and with the correct yaw angle (i.e. maintain the horizontal pitch of the cross pipe.) For the moment, the plan was to leave "E" open and use it as buffer to deal with any misalignment coming from the right side.

This brings us to "F." (The "F" in OMFG!) The challenge here was the same three dimensional puzzle as "D" with the added complexity of joining up with the down pipe from "H." The strategy with "F" was to take a radius and cope out the short end so that it would mate to the back (outside radius) of "I" Then trace the cut-out on "I." As it was curve on curve, I was well beyond my comfort zone.

Once the right side was tack welded, a test fitting provided the good news that there would be no need for a transition pipe at "E," and the vertical, horizontal, and yaw differences could be accommodated by creative cutting, grinding and welding. Time to go through (yet) another cycle of taking parts off, cutting, grinding, tack welding, and re-hanging. Joint "E" also has a major impact on the direction of "I," so one fortuitous by-product of being "real close" is that "I" actually runs parallel to the frame toward the back. (Yippee!)

The end result was a crossover while not perfectly straight, is real close. The bad news is that as a completed assembly the flanges need to be re-clocked slightly (~.25") in order to align all six bolt holes. (Refrain: Time to go through (yet) another cycle of taking parts off, cutting, grinding, tack welding, and re-hanging. )

|

|

|

Whew, that was hard. The good news is that it’s done and the rest of the exhaust system is much easier to work with has m-u-c-h wider tolerances (i.e. room for my lack of skills.)

PS…

If you were wondering about the different color of pipe, the dark pipe sections are part of the header kit, while the lighter pipes are from the U-Bends. Also, the downward bend tacked onto the back of "I" is a simple "tail pipe" that will serve until the rest of the exhaust is assembled.

0 responses so far ↓

There are no comments yet...Kick things off by filling out the form below.

You must log in to post a comment.